HZ-S0206

Ntọala nhazi

Ntọala ntọala

| Nlereanya | HZ-S0206 |

|

Agba okpomọkụ/agba | 2300K |

| 2700K | |

| 3000K | |

| 4000K | |

| 6000K | |

| Eriri ọkụ dabara adaba | 2216-240-24V-3mm |

| CRI | 90 |

| Voltaji (V) | 24 |

| Igwe ọkụ eletrik (A) | 0.48 |

| Ike (W/m) | 5 |

| lm / ogologo ogologo | 107 |

| 108 | |

| 113 | |

| 126 | |

| 130 | |

| Size (mm) | 2.5 × 6 |

| Ogologo ọkọlọtọ | 5000mm |

| Shear unit (mm) | 25 |

| Ogo IP | IP67 |

Usoro waya

Mechanical parameters

Nkwụnye gluu

Usoro mmepụta

Ịzụta ihe akụrụngwa

1.Chip Nhọrọ: Dị ka arụmọrụ chọrọ nke nchapụta, okpomọkụ agba, ntinye ntinye agba na ihe ndị ọzọ dị na mmepụta ngwaahịa, a na-azụta ibe SMD LED dị elu n'aka ndị na-eweta ndị a pụrụ ịdabere na ya. Mpempe akwụkwọ ndị a ga-enwerịrị nyocha nlele tupu ịzụrụ ya iji hụ na akụrụngwa eletriki na ngwa anya dabara n'ụkpụrụ.

2.Circuit Board Ịzụta: Họrọ bọọdụ FPCB dị elu kwesịrị ekwesị, tụọ nguzogide okpomọkụ ya, omume na mgbanwe ya, wee zụta ihe elektrọn dị iche iche achọrọ maka mmepụta n'otu oge, dị ka capacitors na resistors, nke niile ga-enwerịrị ụkpụrụ nke ọma.

3.Auxiliary Material Procurement: Ịzụta ihe inyeaka dị ka ihe ntanye 3M maka mgbakọ warara, tapawa maka ịgbado ọkụ na gluu maka encapsulation na nchebe, ma hụ na viscosity ha, nkwụsi ike na njirimara ndị ọzọ dabara na usoro mmepụta nke warara.

Usoro patch

1.Solder Tapawa Printing: A na-ekpuchi tapawa nke ọma na pad nke bọọdụ sekit FPCB. Iji igwe na-ebi akwụkwọ na-ebi akwụkwọ dị elu yana dị ka ndebiri preset si dị, a na-ahụ na ọkpụrụkpụ na udi nke tapawa solder bụrụ otu na nke ziri ezi, na-atọkwa ntọala dị mma maka patching bead na-esote.

2.Bead patching: Site n'enyemaka nke igwe ntinye akpaka, a na-ejikọta SMD LED beads ngwa ngwa na nke ọma na paịlị na-ebipụta ya na tapawa solder dịka nhazi nhazi. A na-enyocha usoro ihe nchikota site na sistemụ ọhụụ igwe n'oge usoro ahụ niile, enwere ike idozi ntakịrị ihe ndapụta n'oge.

Nyocha anya

Mepụta nyocha anya n'akwụkwọ ntuziaka n'elu eriri ọkụ agbagoro agbagoro.

Ịghaghachi azụ ahịa

1.Parameter Ntọala: Dị ka e ji mara nke solder tapawa na-eji na nkọwa nke beads, jiri nlezianya dozie parameters nke ọ bụla okpomọkụ mpaghara na reflow soldering igwe, gụnyere preheating okpomọkụ, okpomọkụ ọnụego, reflow elu okpomọkụ na jụrụ ọnụego. Ntọala paramita ziri ezi bụ igodo maka ịdị mma ịgbado ọkụ.

2.Welding egbu: Tinye bọọdụ sekit a machiri n'elu eriri ebufe igwe na-agbagharị agbagharị. Ka bọọdụ sekit na-agafe ebe preheating, reflow na jụrụ n'aka nke ọzọ, solder mado na-ekpo ọkụ na-agbaze na ike, na-aghọta na ike eletriki njikọ n'etiti beads na sekit osisi. N'ime oge a, onye na-arụ ọrụ na-aṅa ntị nke ọma na ọnọdụ ịgba ọsọ nke akụrụngwa.

Nyocha na Mmezi

1.Nleba anya: Na-eme nyocha ọhụụ nke mbụ nke warara welded iji lelee ma ọ dị ihe ọ bụla mebere soldering, na-efu soldering, na-aga n'ihu na-akpụ akpụ nke beads, ma ọkpụkpọ ahụ mebiri emebi ma ọ bụ chụpụ ya, yana ma enwere ncha ma ọ bụ ntụpọ ndị ọzọ dị na bọọdụ sekit. .

2.Power-on Test: Jikọọ eriri ahụ na ọkụ ọkụ 24V kwesịrị ekwesị, lelee ọnọdụ ọkụ nke beads, lelee ma ọkụ ahụ ọ bụ otu, ma enwere ọkụ stroboscopic yana ma agba agba ọ dị mma. Kanye akara ngwaahịa ndị nwere nkwarụ wee hazie ndị ọrụ nlekọta ọkachamara ka ha rụkwaa ha.

Neon Extrusion

1.Materials Ngwakọta na nhazi: Tinye ngwa ngwa silicone siri ike na ihe mgbakwunye dị ka vulcanizing agents na igwekota n'otu akụkụ ma kpalie ma tụgharịa ruo mgbe silicone siri ike zuru oke. Maka ụfọdụ ihe pụrụ iche chọrọ nke ibe ọkụ, ọ nwere ike ịdị mkpa ịgbakwunye masterbatch agba na ihe ndị ọzọ iji dozie agba.

2.FPCB nhazi bọọdụ na-agbanwe agbanwe:Bọdụ na-agbanwe agbanwe FPCB nwere bead LED arụnyere na reflow reflow na-edobe ọgwụgwọ ujo ịka nká iji nwalee nkwụsi ike na ntụkwasị obi ya. Mgbe ujo nke ịka nká gasịrị, a na-edobe bọọdụ na-agbanwe agbanwe nke FPCB na bench workbench kpuchie ya na akpụkpọ anụ mgbochi static maka nkewa bọọdụ wee kewaa n'ime ibe FPC na-agbanwe agbanwe. A na-anwale nchapụta nke bead LED ọ bụla, na ndị tozuru etozu na-agbakọta.

3.Extrusion: Kewaa kpalitere na edo siri ike silicone dị ka achọrọ, mgbe ahụ zipu FPC mgbanwe warara n'ime extruder onwem na extrusion anwụ, na-ezite kewara siri ike silicone. N'otu oge ahụ, gbanye oven oven na extruder ma malite extrusion na ịme achịcha. N'oge extrusion usoro, plasticized silicone gbazee na-aga n'ihu n'okpuru ntụgharị nke ịghasa na-agafe na ọnwụ nke extruder. The ịghasa na ịnwụ nke extruder na-arụgide nrụgide na agbaze ka extrude ya n'ime aka uwe ma ọ bụ shei nke neon ìhè warara dị ka udi na size nke anwụ na kechie FPC mgbanwe osisi na ya.

Ịdị jụụ na Ịkpụzi

1.Cooling: The extruded neon ìhè warara ozugbo na-abanye na ngwaọrụ jụrụ, dị ka a jụrụ mmiri tank ma ọ bụ ihe ikuku jụrụ oyi, nke mere na silicone ngwa ngwa jụrụ oyi na-ike na-ejigide udi na size n'oge extrusion.

2. Nhazi:Oghere ọkụ neon mgbe ọ jụrụ oyi nwere ụfọdụ isi ike na nkwụsi ike na enwere ike ịhazi ya ma mechaa gwọọ ya.

Nhazi na-esote

1.Ịcha na ewepụtụ: Bee ma mezie eriri ọkụ neon extruded dịka ogologo achọrọ. Ọtụtụ mgbe, a ga-eji ihe ịkpụ ma ọ bụ ihe eji egbutu ihe iji belata eriri ọkụ ahụ n'ogologo ọkọlọtọ.

2.Nyocha na ule: Mee nyocha anya, nyocha ike, wdg na eriri ọkụ neon na-eji ọkụ ọkụ arụnyere iji chọpụta ma ọnọdụ ikuku ọkụ, ịdị n'otu agba, arụmọrụ eletriki, wdg nke ọkụ ọkụ na-ezute ihe ndị a chọrọ ma wepụ ngwaahịa ndị na-adịghị mma.

Mgbakọ na nkwakọ ngwaahịa

1.Assembly nke Ngwa: Tapawa nrapado 3M n'elu mpempe akwụkwọ a nwalere maka nrụnye na-esote. Maka mpempe mmiri na-ekpuchi mmiri, a ga-emezi ọgwụgwọ mkpuchi ọzọ, a ga-agbakwunye akwa mkpuchi mmiri, gaskets roba na ihe ndị ọzọ.

2.Nkwakọ ngwaahịa na nkwakọba ihe: Ifufe na ngwugwu nke ibe ahụ n'usoro dịka ogologo ọkọlọtọ si dị, dị ka 5000mm kwa mpịakọta, tinye ihe nkiri plastik na nkwakọ ngwaahịa katọn, tinye akara ngwaahịa ahụ, na-egosi nkọwapụta, ụdị, ụbọchị mmepụta na ozi ndị ọzọ, wee gaa n'ihu. ha n'ụlọ nkwakọba ihe maka nchekwa, na-echere mbupu.

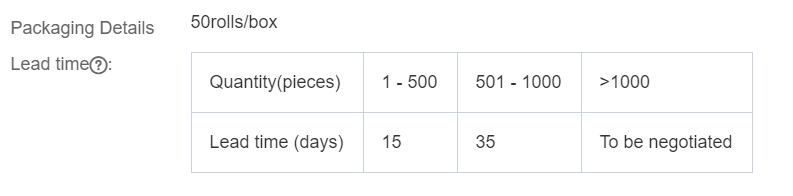

Nkwakọ ngwaahịa & nnyefe

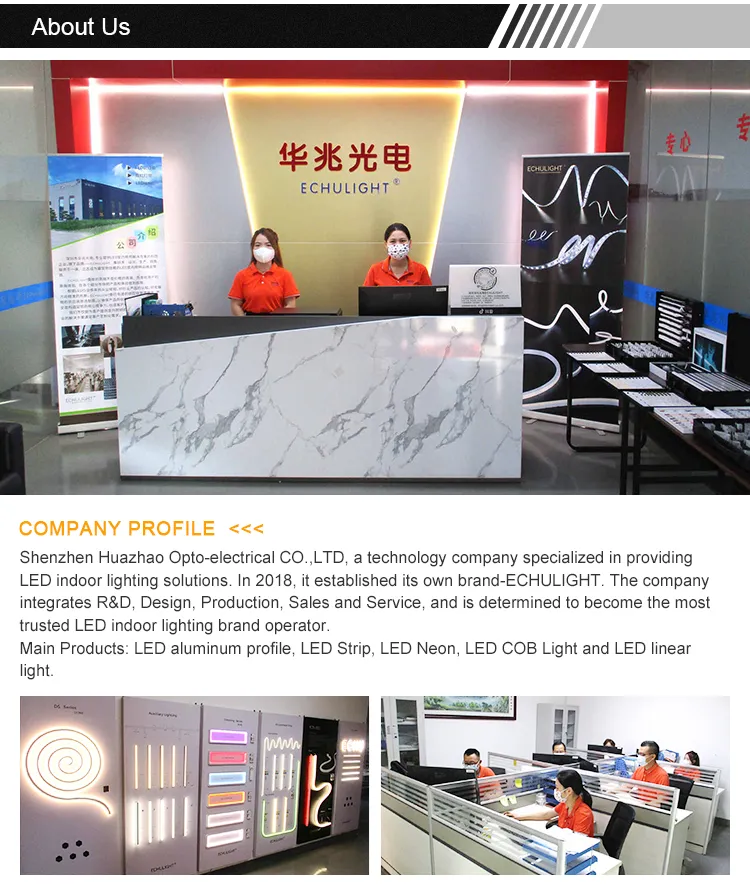

Gbasara anyị

Ụlọ ọrụ anyị

Uru anyị

Asambodo

Mbupu & ịkwụ ụgwọ

FAQ

Ejikọtara yaNgwaahịa

-

Ekwentị

-

E-mail

-

N'elu